Capito, Manchin Announce More Than $1 Million for Entrepreneur Assistance Project in Bluefield5/8/2021

CHARLESTON, W.Va. – U.S. Senators Shelley Moore Capito (R-W.Va.), Ranking Member of the Senate Environment and Public Works (EPW) Committee, and Joe Manchin (D-W.Va.), members of the Senate Appropriations Committee, today announced a $1,095,000 investment for the Center for Applied Research and Technology in Bluefield, West Virginia. This project will foster new businesses, diversify product lines of existing business, streamline manufacturing processes, and create and retain jobs throughout southern West Virginia. This funding was made available through the U.S. Economic Development Administration (EDA), and is expected to create 48 jobs, retain 48 jobs, and generate $2.2 million in private investment.

“Our small businesses in West Virginia are truly the backbone of our economy. It’s great to see this support heading into southern West Virginia to help our entrepreneurs recover from effects of the pandemic and foster new business opportunities. I’m thankful for the role that the Center for Applied Research and Technology is playing in Mercer County, and I commend all they do to create opportunities for economic development in the region. I can’t wait to see the positive impact this project will create in our communities,” Senator Capito said. “Today’s announcement on the EDA’s investment in Bluefield is great news for our state and will spur economic growth in southern West Virginia. The EDA continues to be a strong partner to the Mountain State and this investment to the Center for Applied Research and Technology will support and expand West Virginia businesses, promote new business growth in the region and create and retain good-paying jobs. I will continue to work with the EDA to advocate for funding to boost our economy in West Virginia and I look forward to seeing the economic growth from this project,” Senator Manchin said. https://www.capito.senate.gov/news/press-releases/capito-manchin-announce-more-than-1-million-for-entrepreneur-assistance-project-in-bluefield By CHARLES BOOTHE Bluefield Daily Telegraph May 7, 2021

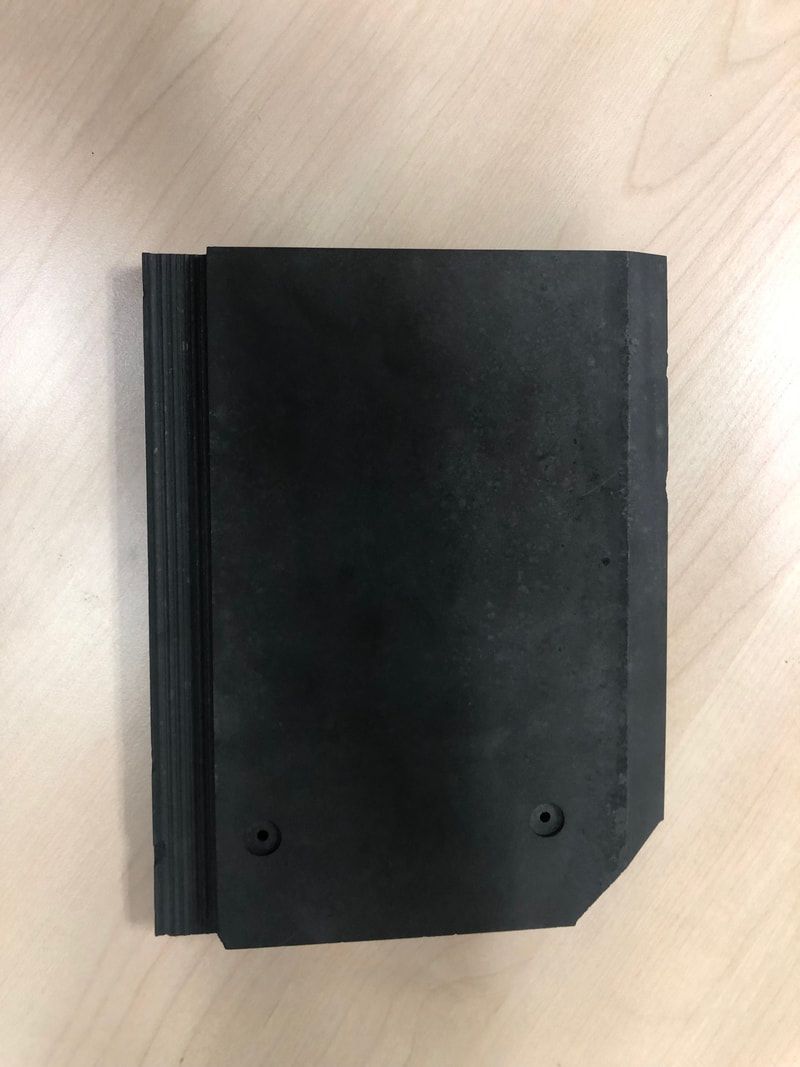

BLUEFIELD — The Center for Applied Research and Technology (CART) in Bluefield is receiving an investment of more than $1 million. Rep. Carol Miller, R-W.Va., made the announcement Thursday, saying the money will provide high-tech industrial supportive services to Bluefield-area businesses and entrepreneurs recovering from COVID-19. “The funds will also create 48 new jobs, save 48 jobs, and bring an estimated $2.2 million in private investment to the region,” she said. “I am thrilled to see the CARES (Coronavirus Aid, Relief and Economic Security) Act continue to help West Virginians recover from this public health emergency.” Miller said the project will support new businesses, strengthen the manufacturing industry, and foster job growth and retention in southern West Virginia. “With welcomed investments as this, we are one step closer to defeating COVID-19, getting hardworking West Virginians back to work, and revitalizing our economy,” she said. The CARES Act passed Congress and was signed into law by former President Donald J. Trump on March 27, 2020 in response to the COVID-19 pandemic. It provides the federal EDA with $1.5 billion for economic development assistance programs to help communities prevent, prepare for, and respond to the pandemic. The City of Bluefield has been working with CART, located on the campus of Bluefield State College, for several years, especially at the Commercialization Station, a start-up incubator for manufacturing businesses. Bruce Mutter, director of CART, previously said CART brings “ingenuity to industry” and helps with training and programs at the Commercialization Station, assisting in many areas in technology, from a drawing to prototypes to circuit boards. According to its website, CART is an independent, non-profit, non-stock corporation under the general corporation laws of the State of West Virginia organized exclusively for educational and scientific purposes. It is designed to foster and support applied research in the Bluefield area for entrepreneurs, inventors, engineering professionals and small technology-based businesses. — Contact Charles Boothe at [email protected] https://www.bdtonline.com/news/cart-to-receive-more-than-1-million-cares-act-funding/article_3e9c64d8-aec9-11eb-8316-07d2dca87277.html  November 11, 2020 WV Executive Magazine Posted In: Executive Exclusives By Michael Murawski One day after a four-hour practice session, a guitarist who had been playing for 27 years thought to himself how cool it would be if his guitar pick could give him a printout of everything his picking hand had done during the session. That guitarist is Michael Murawski, and this internal monologue got the ball rolling for a new business venture. Murawski reached out to Brad Egler, a friend from high school who works as a software architect, and, after exploring the possibilities over lunch, Egler wanted in. Testing the Waters Together the duo built a working prototype using off the shelf components, including a circuit board, pressure sensors and a 3D-printed shell with a reinforced tip. A couple hundred hours of software development later, they had a working app and proof of concept for guitarists to start trying out, and Pickatto LLC was born. The effect of the pick is very similar to fitness trackers people use to monitor daily movement. Developing the picking hand takes millions of repetitions just like exercise. When humans can see their efforts in numbers, it becomes easier to set and meet goals. Very similar to someone who won’t get off the treadmill until they hit their 5-mile goal, a guitarist won’t be satisfied with their session until they have hit their picking goal for the day. Next, the team needed to get the prototype in the hands of guitarists to try, so they paid for a booth at the largest music convention in the world: the National Association of Music Merchants show in Anaheim, CA. With two prototype picks in hand, Murawski and Egler set out to explore if there was truly a market for a product like this. The initial feedback was overwhelmingly positive from guitarists who tried the pick while watching their stats on a screen in front of them. It was clear the duo should move full speed ahead.  From Research to Reality The team’s initial product model will have many software features for users, and the pick will be able to track all plucks against the strings while distinguishing down- and up-strokes. It will come with a custom charger to house the pick and keep it from getting damaged during charging. Pickatto will use Bluetooth technology to stream this information to the user’s phone. The pressure sensor embedded in the pick will let the user know in live time if they are tensing up and squeezing too hard on the pick. “I have pain in my thumb when I play, and I think it is from squeezing the pick too hard over all the years of playing. I wish I would have had this pick many years ago to keep track of this,” says Mark Koch, longtime guitar instructor at the Mary Pappert School of Music at Duquesne University in Pittsburgh, PA. Murawski and Egler are now connected with The INNOVA Commercialization Group, a venture development initiative of the High Technology Foundation that provides access to commercialization services, strategic planning, professional and technical assistance and early stage capital. “Pickatto was a great candidate for enrollment in a new initiative instituted by INNOVA: The 3 Steps to Start-Up program,” says Guy Peduto, director of INNOVA. This collaborative program links the resources of TechConnect West Virginia, INNOVA and the West Virginia Jobs Investment Trust to provide assistance to an early-stage entrepreneur. “This is a perfect product development model that can take advantage of all the assets in our program to create a business from concept to market introduction,” says Peduto. Through the 3 Steps program, Pickatto was introduced to the Center for Applied Research and Technology to build the production model and custom charger. The center is located on the campus of Bluefield State College, and the personnel provide evaluation, prototype development and product design. The team is currently going through multiple phases to get the pick to meet the desired specs to be functional and comfortable for a guitarist to use. Murawski and Egler have visions of Pickatto being a stand-alone product as well as possibly linking up with preexisting software. Until now, guitar instruction software could only monitor and train a guitarist on their fretting hand because there has never been a way to get data directly from the picking hand. Pickatto will finally allow guitarists to be trained and scored on both hands. “This pick could change the way we play a stringed instrument. It is definitely going to be a game changer,” says Rich Engler, legendary concert promoter and producer. Pickatto LLC has an official U.S. patent and copyright on the name, and Murawski and Egler have formed a limited liability company in West Virginia. About the Author Michael Murawski is the co-founder of Pickatto LLC. He received a bachelor’s degree from Duquesne University before going on to work as a customer service specialist in multiple fields. He leads a stress-free lifestyle, which allows him time to stay active, practice his guitar and follow his dream of getting the Pickatto project off the ground. http://www.wvexecutive.com/pickatto-quantified-musician-technology-created-in-the-mountain-state/  Contract to be used to develop commercially-useful components from coal waste ORLANDO, Fla. (August 2020) – Semplastics and its Advanced Materials Division X-MAT® have been awarded $1.4 million in funding by the Department of Energy for a cost-shared research project to develop high-strength, commercially-useful components made from coal waste. “’One person’s trash is another person’s treasure’ is a saying our team has taken to heart,” said Bill Easter, founder of Semplastics and X-MAT®. “We’re working to create a circular economy where we take coal waste materials and turn them into something remarkable. We’re already seeing great progress with prototypes.” This coal waste project could very well lead to progress on the ultimate dream for X-MAT® technologies – to construct a house completely from coal-derived building materials. One day, people will be able to live in a safer, more durable home with everything from the front stoop to structural walls to the roof tiles on top made out of coal and its waste products. “X-MAT®’s revolutionary technologies are coal reimagined,” said Easter. “Our vision for the re-use of coal and coal waste products is a major reason why the Department of Energy is interested in our R&D. We’re transforming an old energy product into something that will one day be used in all types of commercial businesses and potentially even residential architecture. In total, we’ve received $4 million in grants and contracts for our efforts to safely use coal in new ways.’’ Semplastics and X-MAT® are working in concert with the University of North Dakota Energy and Environmental Research Center (EERC) and Center for Applied Research and Technology (CART) in West Virginia on this project. The company also has several other coal and coal waste projects in the works. X-TILES™ are the company’s ecofriendly roof tile that are lightweight, fireproof and can withstand extreme temperatures. Using a patent-pending X-MAT® coating technology, Semplastics is also on the edge of a breakthrough combining coal with waste graphite to create a lithium ion battery anode, which has more energy capacity than never-used graphite. This new contract is just the latest in funding support from the DOE National Energy Technology Laboratory (NETL). The NETL has also awarded Semplastics and X-MAT® a $1.5 million grant for the X-TILES™ and a nearly $1 million contract to help fund the research for turning coal into battery materials. About Semplastics Semplastics, a Florida-based material engineering company, launched in 2000. Over the last 20 years, Semplastics has supplied plastic engineered components to a broad range of industries from medical to aerospace. The Advanced Materials Division of Semplastics, X-MAT®, was later formed in 2013. Since inception, X-MAT® has developed a revolutionary, high-performance material that combines properties of metals (electrical conductivity), engineering plastics (lightweight) and ceramics (high operating temperature). Semplastics has held partnerships with NASA, Space Florida and the Department of Energy. Its game-changing material has various current applications including fireproof roof tiles, lightweight space mirrors, battery electrodes and 3D printing ceramics. Semplastics’ technology can be custom-engineered to fit many specifications and has unlimited potential market applications. To learn more about Semplastics and X-MAT®’s capabilities and future projects, contact us or call (407)353-6885. Semplastics wins $1.5 million Department of Energy grant for West Virginia coal-infused roof tiles8/16/2019

X-MAT® uses coal to create eco-friendly, safe product  Semplastics, through its Advanced Materials Division, X-MAT®, has secured a second Small Business Innovation Research grant from the Department of Energy’s NETL lab. The award was given for the development of its value-added coal roofing product, the X-TILE™. The Phase 2 grant provides the company with $1.5 million. X-MAT® roofing tiles are lightweight, fireproof and can withstand extreme temperatures. They also have higher flexure strength than ceramic roof tiles currently available on the market. X-MAT® CEO Bill Easter said, “There is a great deal of excitement about the progress we made over the last year and we are looking forward to the next phase. We are very thankful to the NETL and our friends in West Virginia for helping us secure this critical grant.” Easter continued, "The value of the roof tiles is more than just science. The success of this next generation of roofing tiles makes America's homes safer and leads to a productive way to use coal. It is our mission to use X-TILE™ technology to provide jobs and future manufacturing in the Appalachian region." X-MAT®’s progress on the tiles was made possible by an initial Department of Energy grant. Through a partnership with West Virginia’s Center for Applied Research and Technology (CART), the company was able to create a first-generation prototype of the X-TILE™. The X-TILE™ uses X-MAT®’s innovative composite material, which combines the properties of metals, plastics and ceramics in one unique material. X-MAT®’s coal-core composite is made of a polymer-derived ceramic that when mixed with coal, does not burn the fossil fuel. As a result, the process reduces the carbon footprint for both the roofing and coal industries in the Appalachian region. About X-MAT®, the Advanced Materials Division of Semplastics X-MAT®, the Advanced Materials Division of Semplastics, launched in 2013. X-MAT® developed a revolutionary high performance material that combines some of the best properties of metals (electrical conductivity), engineering plastics (lightweight) and ceramics (high operating temperature). X-MAT® has had several partnerships including work with NASA, Space Florida and the NETL. X-MAT®’s game-changing material has various current applications including fireproof roof tiles, lightweight space mirrors, battery electrodes and 3D printing ceramics. X-MAT® technology can be custom-engineered to fit many specifications and has unlimited potential market applications. To learn more about X-MAT® capabilities and future projects, visit their website at https://www.x-materials.com or call (407)353-6885. Media Contact Will Wellons Wellons Communications 407-339-0879 [email protected]  24 June 2019 By Conor Griffith Business Editor, The State Journal BLUEFIELD — One company with operations in West Virginia and Florida seeks to make high-tech use of the Mountain State’s most iconic resource and establish new manufacturing jobs in the process. Dynamic Material Systems, led by husband and wife Bill and Sue Easter, is located in Florida but does business in West Virginia as X-MAT. It’s a composite company that found the Mountain State’s coal to be the missing ingredient for polymer ceramics. “These polymer-forming ceramics have been around for 40 years, and what we’ve done is move them into bulk sizes and shapes,” Bill Easter explained. “They’re usually used as coatings and fibers, very small-scale kinds of parts. We started a lab about six years ago, and we had a problem where we needed a carbon source, so we tried coal as our carbon source, mixing it with our material, and we got fantastic results. That’s how it all started.” Unlike other processes, Easter said X-MAT’s manufacturing procedure uses entire particles of coal in its proprietary formulation. He added that the process sequesters the carbon, meaning it releases no greenhouse gases, and the coal does not burn because of the relatively lower temperatures used. “There’s lots of coal, and we need all kinds of ways to use it to turn it into products,” Easter said. The coal and polymer are transformed into a ceramic that can be used as roof tiles that are not only stronger than those on the market, but also lighter — 2-3 times lighter than other ceramic tiles and 4-5 times lighter than those made of metal. Easter said X-MAT is also exploring the use of coal in lithium battery anode materials because coal has better energy properties than what is currently used in this application. “Right now, they use graphite in your cellphone,” he explained. “If you drive a hybrid vehicle or use a calculator, your lithium battery would use graphite as the anode material, and now we’re looking to using coal-based anodes. Coal has this reputation as being dirty, but it could be part of the renewables because batteries are the key. That’s the missing piece.” Easter said that while the company’s research lab is in Florida, X-MAT seeks to set up a manufacturing center in Mercer County’s Bluefield. That, he said, is in order to be close to needed coal supplies. Because of Bluefield’s long history of industry and railroads in support of coal, it was the perfect choice. Having lived in West Virginia for a time, Easter said the biggest difference between Texas and the Mountain State is that the former turns its oil into chemicals and other products before shipping it out. He wants X-MAT to be part of a value-added chain that manufactures a product while benefiting surrounding communities in West Virginia. Easter said another critical component of this work with coal is Bruce Mutter, an engineering professor at Bluefield State College and leader of the Center for Applied Research & Technology. “He’s helping us take it from the R&D stage and turn in production, and he’s fantastic,” Easter said, adding that Mutter made the location in Bluefield possible by knowing the area and local rules and regulations. “He cares deeply about his community, and he really wants to bring business to his area.” Also moving X-MAT’s work forward is a Small Business Innovation Research (SBIR) grant that encourages smaller businesses to engage in research that can be useful for government agencies but also has potential for commercialization. Easter said he received a Phase I grant from the National Energy Technology Laboratory in Morgantown. A Phase I grant seeks to establish merit and commercial viability. Easter said he’s now aiming to acquire Phase II funding, which will continue to pay for research and development. Anne Barth, executive director of the nonprofit business development organization TechConnect WV, said X-MAT is a participant in its NextUp West Virginia program, which offers new and existing companies next-stage commercialization assistance and training. Barth said this is possible through support from the U.S. Economic Development Administration and the Claude Worthington Benedum Foundation. X-MAT was first brought to Barth’s attention through Mutter and the Center for Applied Research & Technology “It was exciting to learn about them, not only because their product uses coal in a new way but also because they are familiar with and successful with the SBIR program,” Barth said. “We see this as an emerging advanced material that could be manufactured in West Virginia, and we see that as a positive sign.” Between X-MAT and Touchstone Laboratories in Ohio County, Barth said West Virginia is seeing multiple examples of how coal can be used beyond power generation. She also commended X-MAT’s decision to pursue the value-added business model, which represents a reversal of past trends in which the raw material was simply extracted and shipped elsewhere. “I think that has to do with supporting technology development and encouraging entrepreneurs to look for new uses for coal,” she said. “It reminds me in some ways of the work that’s being done to extract rare earth elements from coal at WVU.” Business Editor Conor Griffith can be reached by at 304-395-3168 or by email at [email protected] September 17, 2018

By: Bill Easter, Semplastics, X-Mat Semplastics (Oviedo, FL) is delighted to announce that it has won a $225,000 SBIR Phase I grant from the U.S. Department of Energy (DOE) for the initial development and validation of its patented X-MAT coal core composite roof shingles. The X-MAT material, a composite made of polymer derived ceramic (PDC) and West Virginia bituminous coal, enables the beneficial use of coal without burning it. Semplastics has formed a West Virginia company doing business as X-MAT CCC. X-MAT is currently working with the Center for Applied Research and Technology, Inc. (CART) in Bluefield, WV and TechConnect WV as part of their NextUp WV program to build a coal-based West Virginia business. “This disruptive technology is important because it offers a way to use coal to make roof shingles that are twice as strong as conventional shingles at less than half the weight,” Bill Easter, the founder of Semplastics said. Easter added that X-MAT shingles also offer good UV stability, low water absorption and high sound dampening properties, making it an ideal roofing material for the solar panel industry. Reports have indicated that the lifespan of a solar installation will typically reach 20 years. Industry experts report a faster degradation of roofing structures that receive a solar installation. For asphalt roofs, the lifespan will fall to less than 20 years for those that receive solar installations. Semplastics views this gap as an opportunity for X-MAT roof shingles. With the SBIR Phase I award, they expect to develop various types of X-MAT roof shingles for the market. “The $225,000 SBIR Phase I award from the DOE will enable us to build the next generation roof shingle for the solar industry. Since the X-Mat material uses up to 60% coal, the roof shingles will support jobs in the coal industry and jumpstart domestic manufacturing of ceramic tiles,” stated Easter. “Greater than 98% of the ceramic tiles in the U.S. market are imported, so we hope to receive additional government support and continued investor interest.” The residential solar industry, on average, has been growing by 50% annually for the last decade, thus the market focus by Semplastics appears to be quite promising. In addition to roof shingles, Easter said that this unique material has demonstrated application potential in bearings, substrates for high end mirrors, proppants for hydraulic fracturing and most recently, as electrode materials for lithium ion and lead acid batteries. For more information about Semplastics and the X-Mat roof shingles, contact Bill Easter 407-353-6885, [email protected], or X-materials.com/News. By Charlie Boothe Bluefield Daily Telegraph 19 May 2018 BLUEFIELD — The Wellmore Coal Company Red team took first place at the 12th annual Mine Rescue competition, held at Bluefield State College Saturday. Nine of the region’s mine rescue teams competed. Resources Southern WV Team #1 took second place, and the Buchanan Minerals Black team took third place. Other teams competing included Alpha Natural Resources Southern WV #2, the Buchanan Red team, Southern Pocahontas Apache team, Pocahontas Mine Rescue-United Coal, Greenbrier Minerals-Central Appalachian, and the Nicholas Contura team. The contest took place on the June O. Shott Field at BSC, with representatives of the Mine Safety and Health Administration operating an on-site command center that responded to the scenario as if it were a real incident. Team members in the command center maintained constant communication with their teammates on the field, digitally mapping the course and recording real-time gas readings as those on the field advanced through the problem. Developed by the Welch Post #1 known as the “Smoke Eaters” of the National Mine Rescue Association, the competition challenged teams to use skills and technology to solve a rescue scenario within a 70-minute time limit. The team finishing the course in the shortest time with the fewest mistakes wins the challenge. The competition is hosted at BSC and sponsored by Brick Street Insurance, the Welch Post#1 Smoke Eaters and the Center for Applied Research and Technology, Inc., (CART). — Contact Charles Boothe at [email protected] By CHARLIE BOOTHE Bluefield Daily Telegraph 25 March 2018

After almost a year and a half of working on the nuts and bolts of making a project happen, the renovation work at the city of Buefield’s Commercialization Station is finally ready to go out for bids. More than $2.5 million has been earmarked for the station, with about $2.1 million from the federal EDA (Economic Development Administration) and $510,000 from the Shott Foundation. The announcement for these grants was made in October 2016 as the station was getting off the ground. Located in the old freight station on Bluefield Avenue, it is designed to be a business incubator focusing on manufacturing and entrepreneurship. Of course, as we all know, the wheels of government move slowly, and after the announcement was made the process began of seeing the plans come to fruition. That process included many hoops to jump through related to the EDA, including the approval of final engineering reports, which is a steep hill to climb. But it’s finally done, with everything in place to allow companies to bid on the work at the 60,000-square-foot facility, which includes electrical upgrades, new lighting, doors and windows, among other improvements. Bids are due May 2. Jim Spencer, the city’s economic development director and the force behind the station, has asked city board of director members to place the renovation work as an action item on each meeting starting in May. That is necessary because deadlines for approvals must be met as things surface during construction. Economic development is a far cry from what it used to be, and the city as well as the region are making adjustments. No longer can anyone depend on a coal boom. The economy had to diversify and that is what is happening. We all know the impact that tourism is having related to the popular ATV trails in the area and other initiatives planned to make this area a destination. But it takes more than that, and Spencer and the city are focusing on building businesses from the ground up with entrepreneurship. That is precisely what the Commercialization Station is all about and those who take advantage of it will have plenty of help. The city has many partners that are ready and willing to help entrepreneurs get their ideas off the ground, and do it in the station. In fact, another EDA grant for $750,000 was announced in October 2017 for the Center for Applied Research and Technology (CART) Inc., a Bluefield-based partner with the city on the station. “This will be almost like phase two of the project,” Spencer said of what the grant money will do. “CART will develop programs (for the station) that create jobs.” Bruce Mutter, CEO of CART, said the purpose of the project is to provide technical assistance and related support services to technology-based small businesses and entrepreneurs. We are excited about this project and look forward to seeing the old freight station becoming an integral part of the city and of economic development. We are also pleased to see the city place an emphasis on entrepreneurship, which allows local talent to surface and thrive. The station will provide what they need to do that. — Contact Charles Boothe at [email protected] 'Master plan’ for development: Appalachian Power distributes grants to help spur economic growth12/9/2017

A grant from Appalachian Power Company is helping spur a move to create economic development around Exit 1 on Interstate 77 in Bluefield. The grant of $12,500 to the City of Bluefield is “to support development of a comprehensive master plan for an 80-acre, city-owned business park,” the company said. The city purchased and annexed the land, which is on John Nash Boulevard around the Bluefield Area Transit (BAT) headquarters, and has been exploring ways to maximize its potential. By JESSICA NUZZO Bluefield Daily Telegraph A grant from Appalachian Power Company is helping spur a move to create economic development around Exit 1 on Interstate 77 in Bluefield. The grant of $12,500 to the City of Bluefield is “to support development of a comprehensive master plan for an 80-acre, city-owned business park,” the company said. The city purchased and annexed the land, which is on John Nash Boulevard around the Bluefield Area Transit (BAT) headquarters, and has been exploring ways to maximize its potential. By JESSICA NUZZO Bluefield Daily Telegraph By CHARLIE BOOTHE Bluefield Daily Telegraph Dec 9, 2017 BLUEFIELD — A grant from Appalachian Power Company is helping spur a move to create economic development around Exit 1 on Interstate 77 in Bluefield. The grant of $12,500 to the City of Bluefield is “to support development of a comprehensive master plan for an 80-acre, city-owned business park,” the company said. “We own a little more than 80 acres at Exit 1,” said Jim Spencer, the city’s economic development director. “Not all of it is developable, though.” How big the business park can be has not yet been determined. The city purchased and annexed the land, which is on John Nash Boulevard around the Bluefield Area Transit (BAT) headquarters, and has been exploring ways to maximize its potential. “A master plan will look at road access, infrastructure and pad development,” he said. “That will determine how much of that land can be developed.” Spencer said he applied for the grant as part of leveraging another grant from the Shott Foundation. “It is matched with money from the Shott Foundation,” he said. “They had previously given us some money (for the master plan).” Before any development can be done, the plan has to be completed. “This will give us hard data to use in the plans around Exit 1,” he said. “This is seed money to help us plan for first-class development.” Spencer said work on the plan should begin early next year. Exit 1 has been the focus of the city for some time because of its potential for commercial development, but the terrain has always been a challenge, he said, adding that the master plan will help lay the foundation for appropriate growth. The city is also promoting a plan to use the former Consol building nearby on John Nash Boulevard for a Veterans Administration clinic. The one in Princeton is too small and the VA is searching for a new location. The clinic, which is part of the Beckley VA Medical Center, is in a facility on North Walker Street that limits the services that can be offered.City Manager Dane Rideout said recently the Consol building would work well for a VA clinic. “We wanted to be part of the discussion,” he said of the search for a new location for the clinic. “It (the current VA clinic site) is under staffed and crammed into a very small space.” Rideout said the Consol building is very close to Exit 1, the BAT and convenient to Bluefield Regional Medical Center. Having the BAT close by is a big asset, he said, because it provides the transportation needed from all around the county and into McDowell County. The decision on where to locate the facility is in the hands of the federal VA, he added. Appalachian Power also approved a grant for $12,500 to the Mercer County Economic Development Authority to enhance and redesign its website. “Our website is around 10 years old,” said Janet Bailey, Mercer County’s economic development director. “It’s in dire need of updating and revising. This $12,500 will help us accomplish that.” Bailey said the website will be more user friendly and allow anyone to access it using their mobile apps. “We want to attract industry, but we want to attract people too,” she said. “It will have a total new look.” The new website should be completed in about six months, she said. “We are really grateful to Appalachian Power.” Spencer also expressed gratitude, and said a grant from Appalachian Power helped with the city’s website, mybluefield.org, as well as the Commercialization Station, which has gone on to receive more than $2.5 million in grant money. The grants target communities affected by a downturn in the coal industry and are part of ongoing efforts to promote economic growth in the company’s service territory. Eight organizations will receive grants ranging from $5,000 to $20,000 through the company’s Economic Development Growth Enhancement (EDGE) program administered by John Smolak, economic and business development director. The funds may be used for site development or to support marketing and promotion, or new business development and retention. Appalachian Power distributes EDGE grants on an annual basis. The company will award $91,000 in EDGE grants to nonprofits and localities this year. “Appalachian Power is proud to partner with our local, regional and state organizations on outstanding economic development projects in Virginia and West Virginia,” Smolak said. “The EDGE Grant’s focus is to help prepare our communities for new job growth and investment opportunities and we want to help them succeed.” — Contact Charles Boothe at [email protected] |

|

|

CART: ingenuity to industry

|

©2024 CART, Inc., All rights reserved. |